A1.7 Critical control points

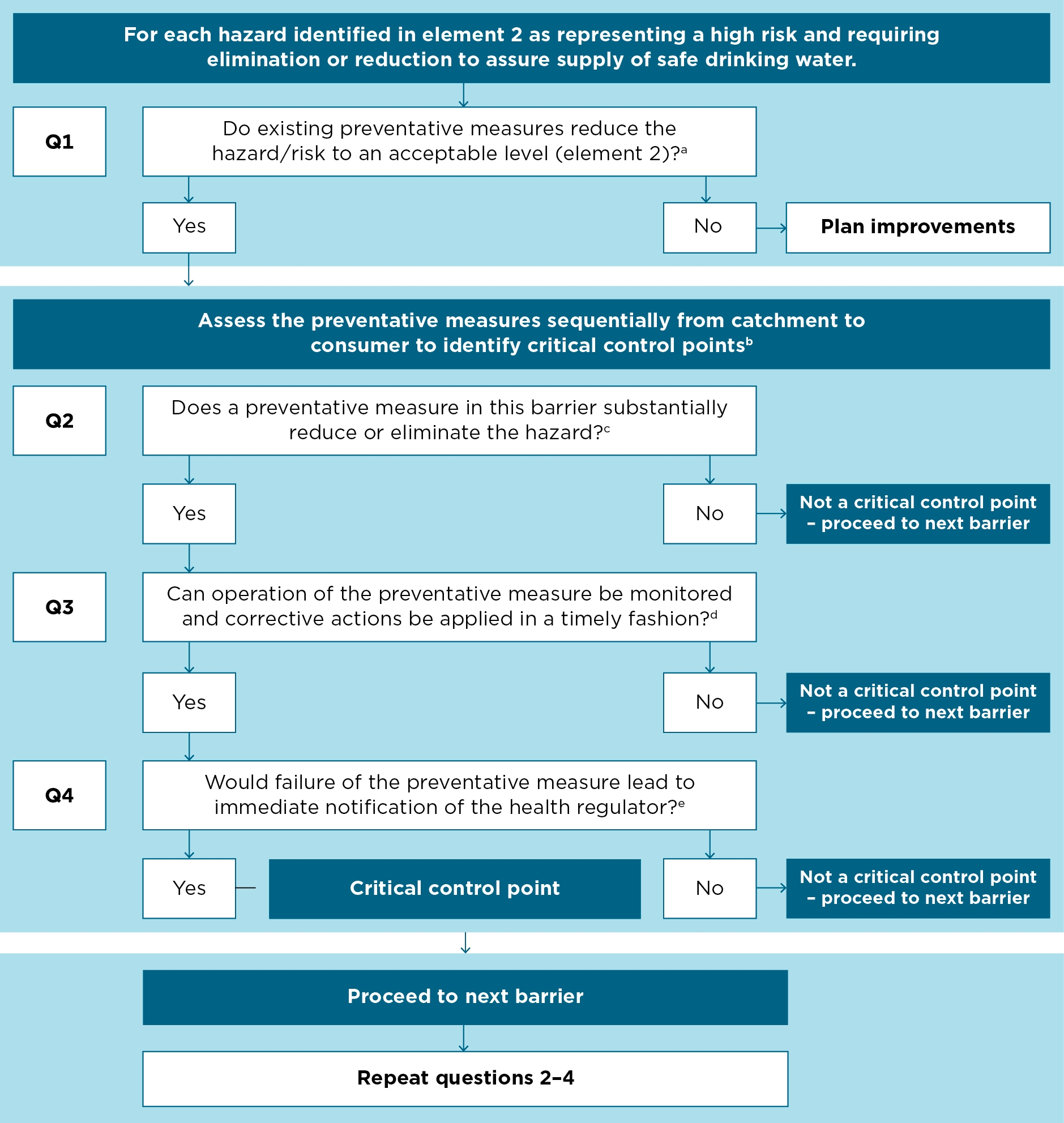

Appropriate selection of critical control points is an important consideration, as increased focus in process control (monitoring and documentation) for a water supply system will be directed toward these activities and processes. The identity and number of critical control points is system specific and will be determined by the range and magnitude of potential hazards and associated risks. Identification of critical control points may be aided by the use of a decision tree, as shown in Figure A1.2.

Critical control points have several operational requirements, including establishing an appropriate monitoring regime specifying specific parameters and critical limits to ensure the process or activity operates effectively. Failure to meet a critical limit represents loss of control of the process and an unacceptable health risk, either directly, through the supply of unsafe water, or indirectly, where multiple critical control points exist, by exceeding the capacity of subsequent processes. Corrective actions must also be available to re-establish process control when criteria have not been met.

If there is a deviation from a critical limit corrective actions also must be available to reduce the health risk from hazards present in the system.

Summary of actions

Assess preventive measures from catchment to consumer to identify critical control points.

Identify procedures required for processes and activities from catchment to consumer, including microbial health-based targets (see Section 3.4 Operational procedures and process control).

Document the critical control points and criteria.

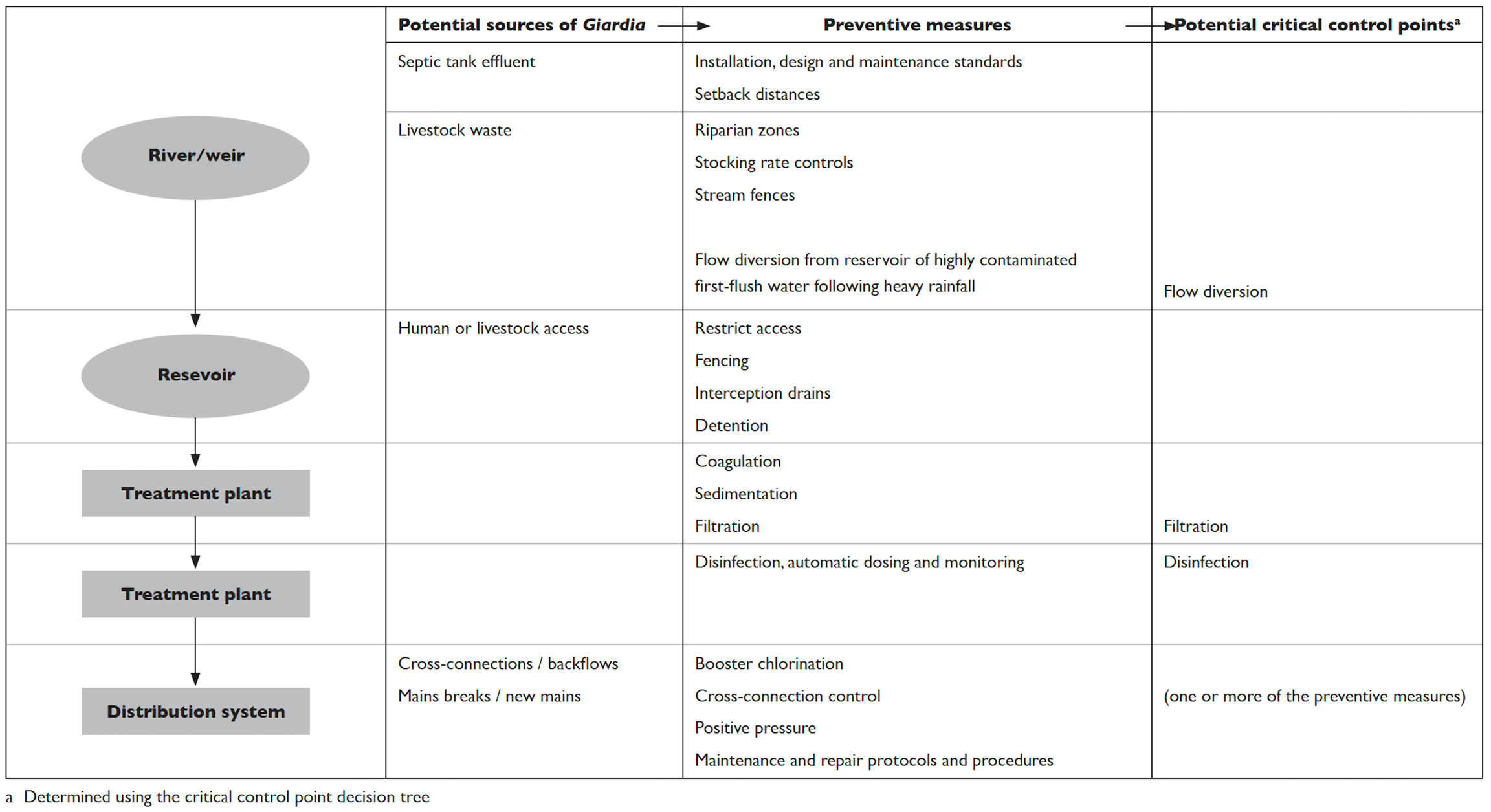

Table A1.9 provides examples of potential sources of Giardia, preventive measures and potential critical control points from catchment to consumer for a river system. In combination, these need to achieve the LRVs described in Table 5.5. Table A1.10 provides further detail on potential critical control points and operational criteria.

Figure A1.2 Critical control point decision tree

Notes

ᵃ Preventive measures should be applied from catchment to consumer in accordance with the multiple barrier approach. Overall, when considered together, these preventive measures should prevent or reduce the hazard to an acceptable level.

ᵇ Drinking water systems generally include numerous preventive measures and strategies that all contribute to assuring the safety of water supplied to consumers; however, only a limited number are amenable to selection as critical control points. The identification of critical control points is system specific and involves making judgments based on knowledge of the potential hazards and associated risks, and the preventive measures. Each significant hazard identified should have a critical control point. However, there may be more than one critical control point to address the same hazard, and more than one hazard may be prevented or reduced by a specific critical control point. Appropriate selection of critical control points is an important consideration because the focus in process control (monitoring and documentation) will increasingly be directed toward these processes and activities. Too many critical control points may make the system unwieldy and too few may fail to provide adequate assurance of drinking water quality.

ᶜ Important considerations are that the preventive measure is essential for significantly reducing the given hazard and that the effectiveness of the measure has been validated.

ᵈ Operational control must be provided for the preventive measure to assure its ongoing effectiveness. This includes establishing a monitoring regime to ensure the process or activity operates to requirements. Practicalities of monitoring should be considered. Operational parameters and criteria must be monitored with sufficient frequency to guarantee the critical control point is providing protection against targeted hazards and to reveal any failures in a timely fashion. Corrective actions must be available to regain control immediately when criteria have been exceeded or deviated from.

ᵉ Failure means deviation from a critical limit not from a target criterion (see Section 3.3.2 and 3.4.2). The significance of critical control points is that failure of the process or activity represents an out-of-control hazard. A practical consideration is whether failure of the process or activity (ie loss of control) will result in a (potentially) unacceptable health risk and require immediate notification of the health regulator.

Table A1.9 Example preventive measures and potential critical control points for Giardia — river system

Table A1.10 Example — potential critical control points and operational criteria

Groundwater abstraction

Enteric bacteria, viruses and protozoa from septic and livestock waste; nitrates

Physical surety of bore and radius of protection zone. Absence of E. coli. NO₃ 50 mg/L (as nitrate)

Weekly inspection and testing for presence of E. coli. 6-monthly monitoring of nitrate

Repair fault in bore

Enforce protection zone

Catchment water reception at take off weir prior to reservoir

Higher levels of enteric bacteria, viruses and protozoa from septic and livestock waste following heavy rainfall

Set flow rate and turbidity limits at location upstream of weir

Continuous stream monitoring station

Divert flow away from reservoir intake

Reservoir mixing/ destratification

Cyanotoxins

6500 cells/mL

Target value: 1000 cells/mL

Continuous monitoring of temperature and dissolved oxygen through the water column

Regular sampling; increase frequency following detection of cyanobacteria or in summer

Dose reservoir with copper sulfate

Improve efficiency of mixing

Take reservoir out of service

Filtration

Enteric bacteria, viruses and protozoa

Combined filtered water turbidity < 0.5 NTU 95% of time. Maximum 5 NTU

Target value: < 0.3 NTU at all times

Continuous online monitoring

Identify problem and take action (e.g. repair faulty operation)

Increase coagulant dose

Filter backwash

Primary disinfection and storage

Enteric bacteria, viruses and Giardia

Free chlorine residual > 1 mg/L

Detention >x (to set minimum C.t)ᵃ

Continuous online monitoring and alarms with automatic feedback to chlorine dosing

Flow not to exceed x ML per hr

Increase chlorine dose

Decrease flows to increase detention time

Stop supply

Secondary disinfection

Enteric and free-living bacteria

Free chlorine residual >1 mg/L

Continuous online monitoring and alarms with automatic feedback to chlorine dosing

Increase chlorine dose

Stop supply

Distribution of treated water

Enteric bacteria, viruses and protozoa

Chemical contaminants

Minimum free chlorine residual of 0.2 mg/L at specified locations

Positive pressure at specified locations

Continuous online monitoring

Hydraulic pressure

Increase chlorine dose

Identify and repair source of pressure loss

C.t = contact time; E. coli = Escherichia coli; NTU = nephelometric turbidity unit ᵃ see Section A8 Chlorination as an example of a critical control point